ZWB Grinding Steel Rod for Rod Mill

Cov ntaub ntawv yooj yim

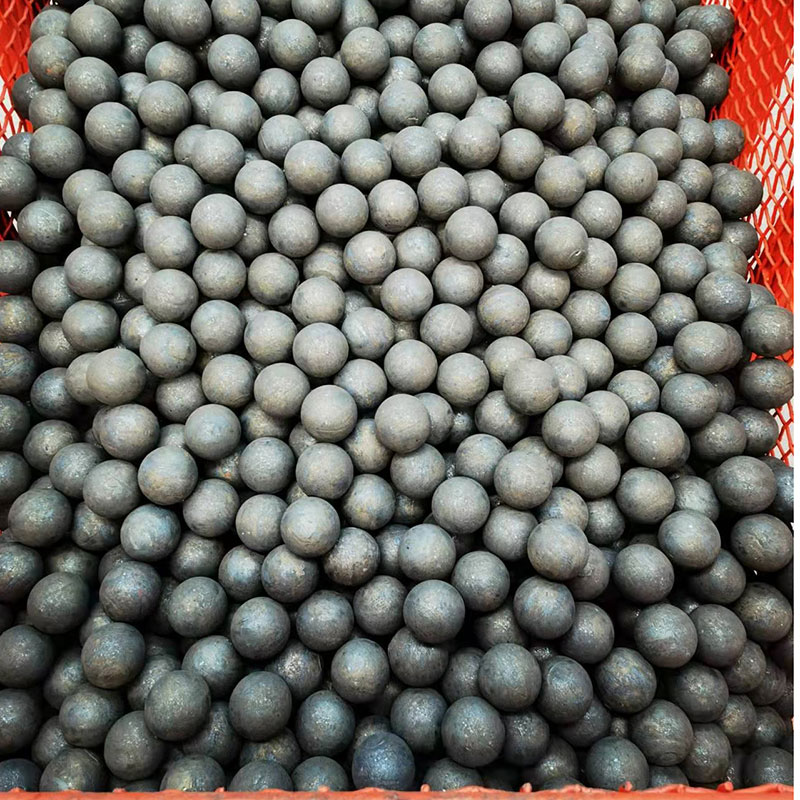

Tangshan ZWell Equipment Manufacturing Co., Ltd. yog Jianlong Group tag nrho cov tswv lag luam tsim cov khoom sib tsoo nrog txhua xyoo muaj peev xwm 100,000mts.Xaiv Jianlong Beiman cov hlau zoo li cov khoom siv raw, ZWell tuaj yeem muab cov khoom siv hlau sib tsoo zoo rau cov pas nrig.

Steel sib tsoo pas nrig yog ib hom kev sib tsoo xov xwm sau rau hauv lub pas nrig zeb.Nws yog dav siv nyob rau hauv kev sib tsoo ntawm metallurgy, tsev cov ntaub ntawv, cement, mining thiab lwm yam kev lag luam.Cov hlau sib tsoo rods yog muab pov los yog swb rau hauv lub rotating qws zeb.Cov ore nyob rau hauv lub zeb yog crushed los ntawm tsiv steel sib tsoo rods, thiaj li mus cuag cov nyhuv ntawm kev sib tsoo.

Xav paub ntau ntxiv txog qhov loj thiab qib, thov hu rau ZWell.

Khoom Index

- Nto Hardness HRC: ≥58

- Core Hardness HRC: ≥55

- Tus nqi cuam tshuam Ak: ≥12J/㎝²

Khoom nta

Cov kab ntau lawm ntse xyuas kom meej qhov ncaj, hardness, toughness thiab tensile lub zog ntawm cov tuav uas muaj peev xwm ua tau raws li daim ntawv thov ntawm ntau hom qws mills.Lub zog muaj zog, siab hnav resistant, tsis muaj tev thiab tsis deformation.

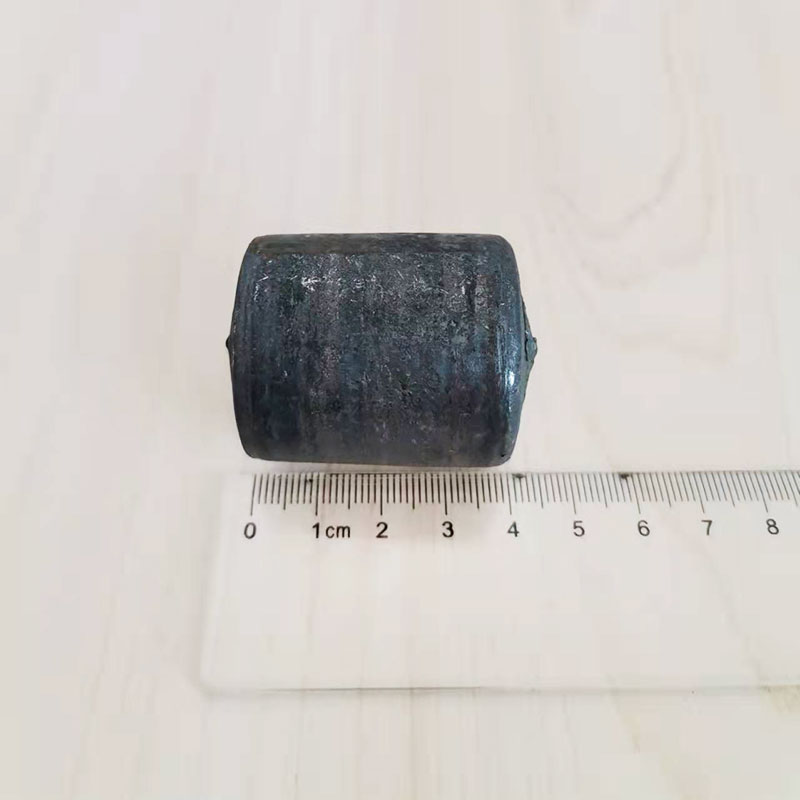

Loj thiab kam rau ua

| Txoj kab uas hla (mm) | Ntev (mm) | Txoj kab uas hla (mm) | Length kam rau ua (mm) |

| Φ50-150 | 2000-6000 | -1.6-0.2 | -20-0 |

Tshuaj muaj pes tsawg leeg

| Qib | C (%) | Si (%) | Mn (%) | Cr (%) | Cu (%) | Mo (%) | P (%) | S (%) | Niag (%) |

| 45 # | 0.42-0.50 Nws | 0.17-0.37 Nws | 0.5-0.80 Nws | 0-0.25 Nws | 0-0.25 Nws | 0-0.30 Nws | 0-0.035 Nws | 0-0.035 Nws | 0-0.30 Nws |

| 60 Mn | 0.57-0.65 Nws | 0.17-0.37 Nws | 0.70-1.0 Nws | 0-0.25 Nws | 0-0.25 Nws | 0-0.30 Nws | 0-0.035 Nws | 0-0.035 Nws | 0-0.30 Nws |

| 65mn ua | 0.62-0.70 Nws | 0.17-0.37 Nws | 0.90-1.0 Nws | 0-0.25 Nws | 0-0.25 Nws | 0-0.30 Nws | 0-0.035 Nws | 0-0.035 Nws | 0-0.30 Nws |

| 40 Cr | 0.37-0.45 dr hab | 0.17-0.37 Nws | 0.50-0.8 hli | 0.80-1.1 Nws | 0-0.25 Nws | 0-0.30 Nws | 0-0.035 Nws | 0-0.035 Nws | 0-0.30 Nws |

| 42CrMo | 0.38-0.45 Nws | 0.17-0.37 Nws | 0.50-0.80 Nws | 0.90-1.2 Nws | 0-0.03 Nws | 0.15-0.25 dr hab | 0-0.035 Nws | 0-0.035 Nws | 0-0.30 Nws |

| ZWB-2 | 0.70-0.80 Nws | 0.17-0.37 Nws | 0.70-0.80 Nws | 0.50-0.60 Nws | 0-0.25 Nws | 0-0.30 Nws | 0-0.035 Nws | 0-0.035 Nws | 0-0.30 Nws |

Technical Specification

| Tus nqi cuam tshuam (J/㎝²) | Hardness (HRC) | Breakage Rate | Tso sij hawm | Kev ncaj | |

| 5-7 | 45-55 : kuv | 1% | ≥ 30 | 2/1000 | |